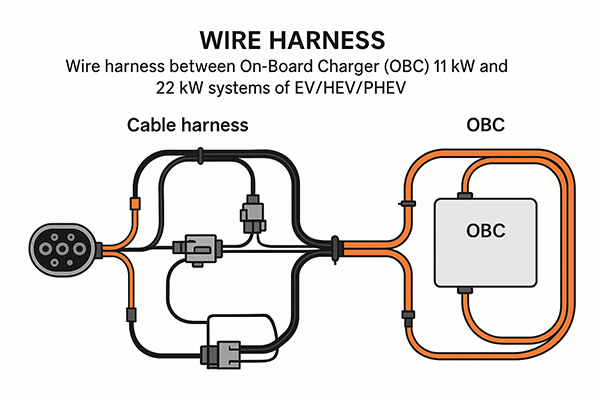

Explore wire harness systems for On-Board Chargers (OBCs) in EVs, HEVs, and PHEVs. Learn about design, safety, architecture, and future trends in electric vehicle wiring.

Wire harness systems are the backbone of electrical connectivity in Electric Vehicles (EVs), Hybrid Electric Vehicles (HEVs), and Plug-in Hybrid Electric Vehicles (PHEVs). This guide dives deep into the integration of On-Board Chargers (OBCs) with power ratings of 11kW and 22kW, focusing on energy conversion, safety protocols, wiring architecture, and system interconnectivity. Whether you're an engineer or an EV enthusiast, understanding harness design is key to optimizing vehicle performance.

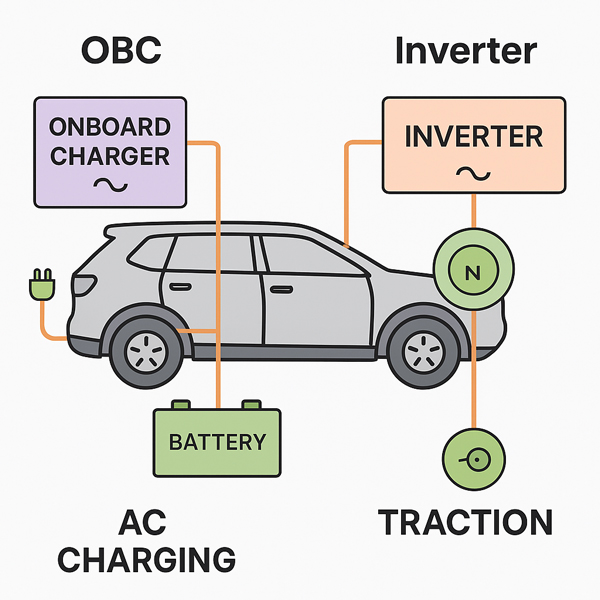

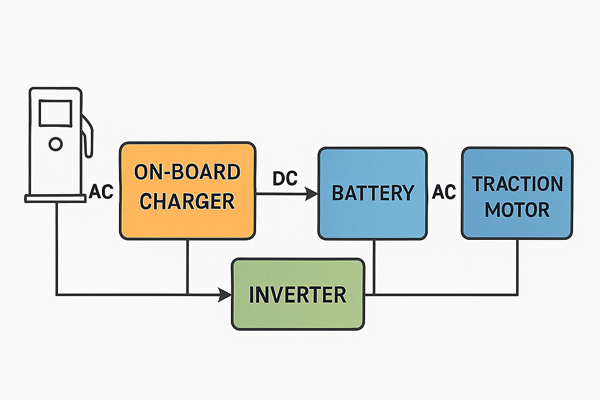

An On-Board Charger (OBC) converts alternating current (AC) from external sources into direct current (DC) to charge a vehicle's high-voltage battery. Unlike inverters, OBCs operate during charging, not driving. The power rating—11kW for moderate charging or 22kW for faster charging—directly impacts wire harness requirements, including load capacity, insulation, and connectors.

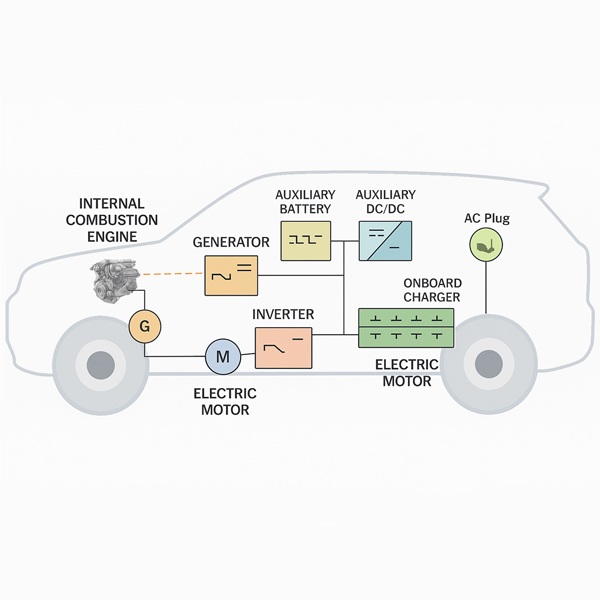

While an OBC handles AC-to-DC conversion for battery charging, an inverter converts DC from the battery to AC to power the electric motor. Their distinct functions and operating times necessitate unique wire harness interfaces. This section breaks down their roles and wiring implications for seamless integration in EVs.

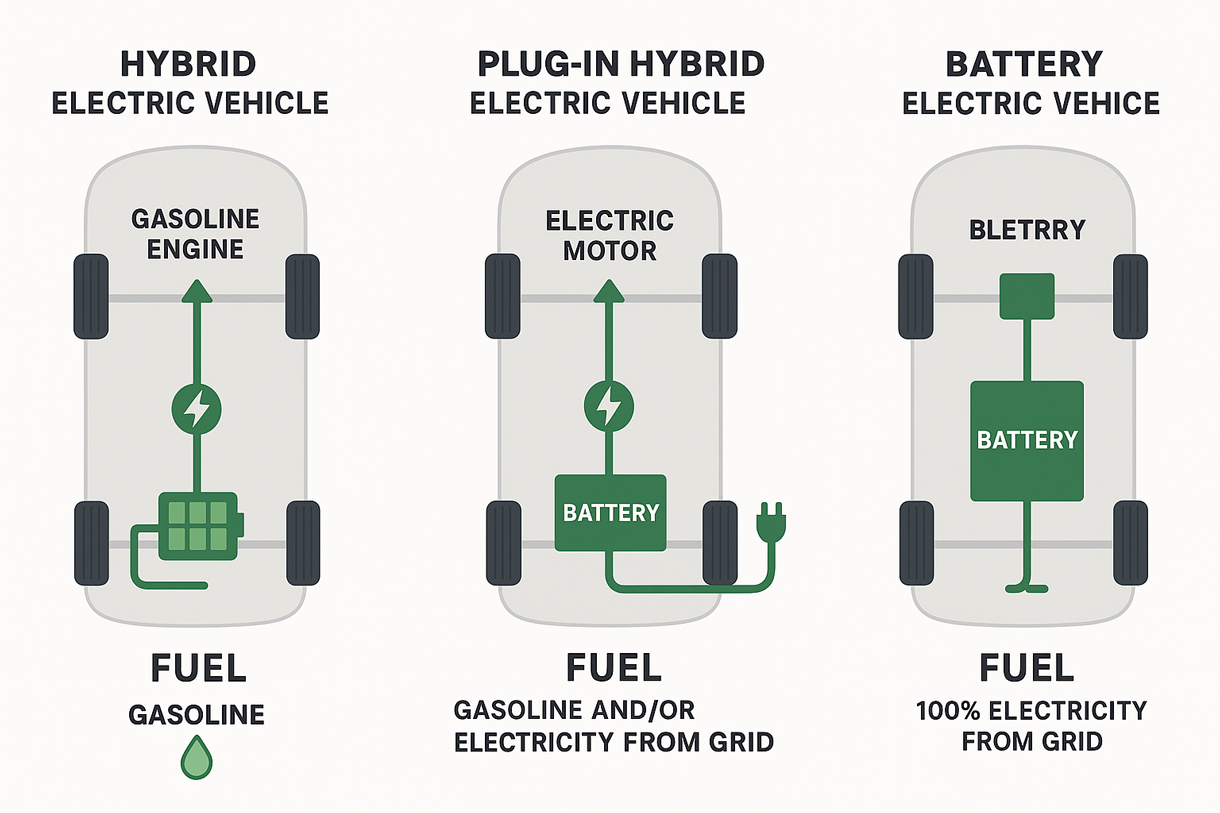

The architecture of Battery Electric Vehicles (BEVs), Hybrid Electric Vehicles (HEVs), and Plug-in Hybrid Electric Vehicles (PHEVs) varies based on power sources and component integration. BEVs rely entirely on electric powertrains, requiring extensive high-voltage (HV) harnessing. HEVs feature compact hybrid layouts with shorter HV lines, while PHEVs balance dual-mode systems for both electric and internal combustion engine (ICE) operations.

Harness needs vary by vehicle type. BEVs require extensive HV harnessing for full-electric operation, HEVs use shorter lines due to compact hybrid setups, and PHEVs need high-capacity connectors to support dual-mode functionality. This section explores tailored solutions for each.

Wire harnesses for OBCs and inverters must support charging inlet wiring, traction interfaces, CAN communication, shielding, temperature sensors, and grounding. This section details their routing and layout to ensure efficiency, safety, and reliability in EV systems.

Safety is paramount in wire harness systems. Key considerations include isolation resistance, thermal shielding, dielectric strength, and EMI suppression. This section explains testing standards and verification processes to ensure compliance with automotive safety norms.

Automotive wire harnesses must endure 10–15 years of operation. Factors like vibration, high temperatures, UV exposure, salt spray, and moisture (IP67/68 standards) are tested through cyclic bending, mechanical fatigue, and connector mating cycles in controlled lab environments.

Harness configurations adapt to operational demands and vehicle types. BEVs suit urban fleets and taxis with zero-emission efficiency. HEVs excel in areas with limited charging infrastructure for long-haul needs. PHEVs cater to short electric commutes with gasoline backup for extended range. Climate zones and component densities also influence design.

As EV platforms evolve, wire harnesses are trending toward lightweight, recyclable, and modular designs. Integration with digital diagnostics, Vehicle-to-Grid (V2G) systems, and advanced thermal/load monitoring is shaping the future of sustainable automotive wiring.

Wire harness systems are critical to the performance and safety of OBC in EVs, HEVs, and PHEVs. From tailored designs for different vehicle types to innovations in sustainability, understanding these systems is essential for advancing electric mobility.

Stay tuned for updates on emerging trends and technologies in EV wiring.

Contact us now | Learn more at Automotive-Solution

Let’s build the future of Electric Vehicle—together.