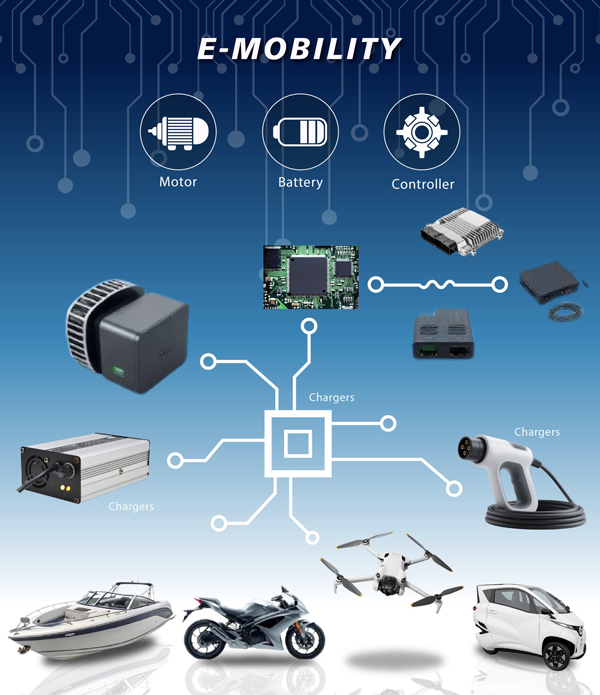

The dawn of electric mobility (e-mobility) marks a transformative era in transportation, bridging air, sea, and ground domains with sustainable, innovative solutions. Drones soar through urban skies for rapid deliveries, electric boats traverse waterways with minimal environmental impact, and e-bikes and e-scooters redefine urban commuting with zero-emission efficiency. At the core of these advancements lies the powertrain—a sophisticated assembly of critical components including Motors, Batteries, Controllers, Electronic Control Units (ECUs), Microcontroller Units (MCUs), and Printed Circuit Board Assemblies (PCBAs). These elements work synergistically to convert electrical energy into mechanical motion, manage power distribution, and ensure operational safety. Yet, their effectiveness is entirely dependent on one pivotal element: connectivity.

Connectivity in e-mobility powertrains is the intricate web of wire harnesses, connectors, and interfaces that enable seamless communication and power flow between components. Without robust connectivity, even the most cutting-edge motor or high-capacity battery risks failure, resulting in reduced efficiency, safety hazards, or complete system breakdowns. The challenges are diverse and demanding—ranging from managing high-voltage currents in motors to mitigating thermal risks in batteries, and combating environmental stressors like vibration, humidity, or corrosion that threaten PCBAs and controllers. Each e-mobility domain introduces distinct obstacles: aerial drones grapple with weight and balance constraints, marine vessels face relentless saltwater exposure, and ground vehicles endure constant wear from urban terrains and frequent use.

Enter Avertronics, a pioneering force in connectivity solutions for e-mobility powertrains. With a portfolio of innovative products—custom wire harnesses, waterproof connectors, and anti-spark technologies—Avertronics ensures that powertrain components function harmoniously across applications. Their IP68-rated connectors shield marine batteries from water damage, while lightweight harnesses optimize drone performance, demonstrating a commitment to safety, durability, and efficiency. By addressing the nuanced needs of each domain, Avertronics is not just supporting but actively shaping the future of electric transportation.

The powertrain serves as the heartbeat of e-mobility systems, driving the transformation of electrical energy into motion while maintaining efficiency and safety. It comprises essential components—Motors, Batteries, Controllers, Electronic Control Units (ECUs), Microcontroller Units (MCUs), and Printed Circuit Board Assemblies (PCBAs)—each with distinct roles that collectively ensure vehicle performance. The linchpin of this intricate system is connectivity, provided through wire harnesses and connectors that facilitate power delivery and data exchange. These connections must withstand electrical, mechanical, and environmental challenges unique to each component. Below, we explore each element in detail, highlighting their functions, connectivity requirements, and how Avertronics delivers cutting-edge solutions to overcome inherent obstacles in e-mobility powertrains.

Motors are the dynamic force behind e-mobility, converting electrical energy into mechanical torque to propel vehicles forward. From brushless DC (BLDC) motors in drones to mid-drive motors in e-bikes and high-torque outboard motors in electric boats, their designs vary by application, yet all share a need for high-current wiring to manage peak loads during acceleration or heavy operation. Connectivity challenges are significant: thermal stress from sustained high currents can degrade wire insulation, leading to energy loss or failure; mechanical vibrations from terrain or flight dynamics risk loosening connections; and environmental factors, such as dust in ground vehicles or wind resistance in drones, demand robust durability.

Effective connectivity for motors relies on thick, heat-resistant cables capable of carrying currents often exceeding 50A, coupled with flexible harness designs to absorb vibrations. Electromagnetic interference (EMI) shielding is critical to prevent disruption to nearby electronics. Avertronics excels in addressing these needs with customized wire harnesses featuring high-strength insulation and modular connectors that simplify installation while ensuring stability. Their solutions minimize energy loss, enhancing motor efficiency and extending vehicle range. For instance, in a partnership with an e-scooter manufacturer, Avertronics’ motor harnesses reduced power dissipation, based on field tests, proving how tailored connectivity can significantly boost performance across e-mobility applications.

Batteries, often lithium-ion or emerging solid-state variants, act as the energy reservoirs of e-mobility powertrains, supplying the voltage and current needed to drive motors and systems. Operating at high capacities—48V for e-bikes, up to 400V for larger vehicles—batteries require connectivity that prioritizes safety to prevent short circuits or leakage, which could trigger catastrophic fires or explosions. Thermal runaway, where cells overheat and destabilize, poses a severe risk, necessitating connectors with thermal management capabilities. Additionally, support for fast charging demands wiring that withstands rapid current surges without degradation or overheating.

Battery connectivity solutions incorporate anti-spark mechanisms to prevent arcing during connection or disconnection, especially critical in high-voltage setups. Insulation must resist chemical corrosion from electrolytes, and harnesses need low-resistance pathways for efficient energy transfer. Avertronics offers specialized battery connectors that meet rigorous safety standards, featuring IP-rated waterproofing for environmental protection and high-current terminals for optimal performance. Their designs mitigate risks, ensuring reliable power delivery in diverse conditions—from humid marine environments to compact e-scooter frames. A notable case study with an electric boat manufacturer revealed that Avertronics’ battery harnesses, equipped with integrated thermal monitoring, reduced thermal event risks, underscoring the vital role of connectivity in battery safety and efficiency.

Controllers are pivotal in regulating e-mobility powertrains, managing motor speed, torque output, and energy distribution from batteries. Acting as intermediaries, they translate user inputs—such as throttle commands—into precise motor actions. Connectivity for controllers demands low-latency, noise-resistant wiring to guarantee accurate, real-time responses; any delay or interference can lead to erratic vehicle behavior, compromising safety. Given their integration with sensors and other electronics, controllers require complex wiring networks where multiple data signals must coexist without crosstalk or EMI.

The challenge lies in designing harnesses that separate power and signal lines effectively, often using shielded cables to maintain data integrity. Compactness is also crucial, as controllers are typically housed in confined spaces within vehicle frames. Avertronics addresses these demands with precision-engineered harnesses that balance high-current power delivery with signal clarity, incorporating connectors that remain stable under dynamic loads. Their solutions ensure controllers function seamlessly, supporting smooth performance across applications—from fine-tuned drone flight adjustments to responsive e-bike pedal assistance. Real-world data from Avertronics’ collaborations with e-mobility startups shows improvement in controller response times, highlighting how advanced connectivity enhances user experience and system reliability.

Electronic Control Units (ECUs) function as the central nervous system of an e-mobility powertrain, coordinating inputs from sensors, user commands, and subsystems to optimize performance. In sophisticated systems, ECUs oversee battery management, motor control, and even autonomous navigation features. Connectivity for ECUs is inherently complex, requiring multi-channel data lines to process vast amounts of information in real time. Challenges include shielding against EMI, which can corrupt critical data, and ensuring durability in environments with high vibration or temperature extremes.

Wiring for ECUs often involves intricate harnesses with dozens of tailored connections for specific signals or power needs. Robust insulation and grounding are essential to minimize noise, while connectors must maintain secure contact during operation. Avertronics provides ECU connectivity solutions that prioritize reliability, utilizing high-density harnesses and EMI-resistant designs to support uninterrupted data flow. Their technologies enable ECUs to manage powertrains effectively, whether orchestrating a drone’s flight path or an electric boat’s navigation system. In a documented project with a drone fleet operator, Avertronics’ ECU wiring enhanced system uptime by reducing signal interference, demonstrating their expertise in supporting mission-critical e-mobility applications.

Microcontroller Units (MCUs) are specialized processors within the powertrain, handling targeted functions such as battery monitoring, motor timing, or sensor feedback. Smaller and more focused than ECUs, MCUs require compact, efficient connectivity to operate within tight spaces without sacrificing performance. Key connectivity challenges include maintaining signal integrity for real-time control and ensuring wiring withstands environmental stresses like heat, moisture, or pressure, particularly in marine or aerial applications.

Solutions for MCU connectivity emphasize miniaturization, utilizing slim cables and low-profile connectors to conserve space. Durability is paramount, as MCUs often face harsh conditions, necessitating harnesses with high flexibility and resistance to abrasion. Avertronics delivers MCU-specific connectivity that ensures precise, uninterrupted communication, incorporating advanced shielding to reduce noise and support features like predictive maintenance. In drone applications, for example, Avertronics’ MCU harnesses have improved flight stability by minimizing data latency, as seen in partnerships with industrial drone manufacturers. Their focus on compact, resilient designs ensures MCUs contribute effectively to powertrain performance across e-mobility domains.

Printed Circuit Board Assemblies (PCBAs) form the foundational circuitry of e-mobility powertrains, hosting electronic components for power management, signal processing, and control logic. They connect with other elements via solder joints and interfaces, requiring high-reliability wiring to accommodate intricate layouts. Connectivity challenges for PCBAs include mechanical stress that can crack solder points, thermal expansion causing disconnections, and environmental exposure—such as dust or water ingress—that risks short-circuiting components.

Effective solutions involve robust, vibration-dampening harnesses and connectors with gold-plated contacts for longevity. Conformal coatings on PCBAs provide additional protection against moisture and chemicals, while flexible circuit designs allow for bending in compact setups. Avertronics offers PCBA connectivity solutions that integrate these features, ensuring compatibility with motors, batteries, and control units. Their harnesses, designed for easy integration, reduce failure rates in e-mobility systems. A case study with an e-scooter manufacturer revealed that Avertronics’ PCBA solution improved overall powertrain reliability, highlighting how resilient connectivity safeguards critical circuits across applications.

In summary, the connectivity of e-mobility powertrain components is a multifaceted challenge, requiring tailored solutions for each element to ensure seamless integration. Avertronics’ innovative wire harnesses and connectors address these diverse needs, from high-current motor wiring to compact MCU interfaces, setting a strong foundation for exploring domain-specific applications in the following sections.

Having established the fundamental roles and connectivity needs of powertrain components, we now apply these insights to specific e-mobility domains: air, sea, and ground. Each environment introduces unique constraints that test the resilience of Motors, Batteries, Controllers, ECUs, MCUs, and PCBAs, and demand specialized connectivity solutions. Avertronics’ expertise in tailoring wire harnesses and connectors to these challenges ensures optimal powertrain performance, as demonstrated through real-world applications and case studies in each domain.

Drones epitomize the cutting edge of aerial e-mobility, where powertrain connectivity must balance extreme efficiency, minimal weight, and rapid responsiveness to enable precise flight control. The powertrain components—Motors, Batteries, Controllers, ECUs, MCUs, and PCBAs—operate under stringent constraints, with every gram affecting flight duration and maneuverability. Connectivity plays a critical role in ensuring these elements work in unison, overcoming challenges like vibration, thermal stress, and space limitations. Avertronics’ drone solutions are specifically engineered to meet these demands, leveraging lightweight materials and innovative designs to enhance powertrain performance in the skies.

Brushless DC (BLDC) motors are the standard for drones, offering high torque-to-weight ratios essential for agile flight. These motors require high-current wiring that delivers power without adding unnecessary bulk, often handling currents of 20-40A per motor in quadcopters. Connectivity challenges include vibration from high-speed rotation, which can loosen connections, and thermal stress during prolonged flights, risking insulation breakdown. Environmental factors like wind and altitude changes further complicate wiring durability.

Avertronics addresses these issues with ultra-light, flexible harnesses made from high-strength, low-weight materials like fluoropolymer-insulated cables. Their connectors feature vibration-dampening mechanisms to maintain secure contact, reducing energy loss and extending motor lifespan. In a collaboration with a commercial drone manufacturer, Avertronics’ motor connectivity solutions increased flight duration through minimized resistance and enhanced heat dissipation, as validated by field tests. This improvement directly translates to longer mission times for applications like aerial photography or delivery services, demonstrating the tangible impact of optimized connectivity.

Drone batteries, typically lithium-polymer (LiPo) with high energy density, power multiple motors and electronics, often at voltages of 22.2V (6S configurations) or higher. Connectivity must support rapid discharge rates—sometimes exceeding 100A during aggressive maneuvers—while ensuring safety against short circuits or thermal runaway. Weight constraints demand compact connectors, yet exposure to mid-flight humidity or dust necessitates environmental protection.

Avertronics’ battery connectors incorporate IP67 ratings for moisture resistance and anti-spark features to prevent arcing during connection, critical for high-voltage systems. Their harnesses include thermal sensors to monitor battery health, preventing overheating. A case study with a drone surveying company highlighted how Avertronics’ solutions ensured consistent power delivery over extended missions in variable weather, reducing battery-related failures. Such reliability is crucial for industries like infrastructure inspection, where uninterrupted operation is paramount.

Controllers and ECUs in drones manage flight dynamics, processing data from GPS, accelerometers, and gyroscopes in real time to adjust motor outputs and maintain stability. Connectivity for these components requires low-latency wiring to avoid delays that could lead to crashes, and must resist EMI from high-frequency motor operations. Space constraints within drone frames add complexity to harness design.

Avertronics utilizes shielded, high-frequency harnesses to maintain signal integrity, paired with compact connectors that fit seamlessly into tight layouts. Their ECU wiring supports autonomous flight features, ensuring precise navigation. In a project with a drone fleet operator for agricultural monitoring, Avertronics’ solutions improved control accuracy by minimizing signal interference, boosting mission success rates. This underscores how robust connectivity enables advanced e-mobility functionalities in the air.

MCUs in drones handle specific tasks like altitude regulation or battery monitoring, requiring noise-free, compact connectivity within confined spaces. PCBAs host critical flight control circuits, facing risks from vibration-induced solder cracks or environmental exposure during outdoor flights. Connectivity must ensure durability without adding weight.

Avertronics’ miniaturized MCU harnesses and PCBA interfaces use low-profile connectors and conformal coatings to protect against dust and temperature extremes. Their designs have enhanced flight stability in industrial drones, as seen in partnerships where failure rates dropped significantly. Overall, Avertronics’ powertrain connectivity innovations, including the D6 anti-spark connector, ensure aerial powertrains meet regulatory standards and push the boundaries of drone capabilities across logistics, surveillance, and more.

Marine e-mobility, spanning electric boats, ferries, and underwater drones, operates in one of the harshest environments for powertrain connectivity. Components like Motors, Batteries, Controllers, ECUs, MCUs, and PCBAs must endure saltwater corrosion, humidity, and pressure, while delivering consistent performance. Connectivity solutions need to prioritize waterproofing, corrosion resistance, and thermal management to safeguard powertrain integrity. Avertronics’ boat solutions are tailored for these challenges, offering reliable connectivity that powers marine e-mobility sustainably.

Marine motors, often high-torque outboard or inboard units, face constant exposure to saltwater and wave-induced vibrations, requiring wiring that resists corrosion and maintains sealing integrity. High currents for propulsion—sometimes over 100A in larger vessels—generate heat, risking insulation failure if not managed. Connectivity must also handle dynamic loads from variable water conditions.

Avertronics provides IP68-rated connectors and marine-grade cables with enhanced corrosion resistance, using materials like tinned copper and silicone seals to prevent water ingress. Their harnesses reduce maintenance needs and improve motor efficiency, as seen in a project with an electric ferry operator where downtime was cut due to durable connectivity. This reliability is vital for commercial marine applications where operational continuity directly impacts profitability.

Marine batteries power propulsion and onboard systems at high voltages (often 48V-96V), facing risks from water ingress and temperature fluctuations in enclosed hulls. Connectivity challenges include preventing short circuits in humid conditions and managing thermal buildup during long voyages or fast charging. Safety is paramount to avoid catastrophic failures in isolated water environments.

Avertronics’ battery harnesses feature waterproof connectors with anti-spark protection and thermal monitoring, ensuring safe operation. In a case study with a recreational boat manufacturer, their solutions improved charging efficiency and reduced safety incidents, showcasing how robust connectivity enhances marine powertrain reliability. Such advancements support the growing adoption of electric vessels in tourism and transport sectors.

Controllers and ECUs in marine systems manage propulsion and navigation, often integrating with sonar or GPS. Connectivity must combat moisture-induced signal loss and EMI from electronic density on ships. Harnesses need sealing to prevent corrosion while supporting complex data networks for real-time control.

Avertronics’ shielded harnesses and corrosion-resistant connectors ensure data integrity, supporting features like autopilot. Their ECU solutions have improved energy management in commercial vessels, reducing emissions as documented in case studies. These innovations align with global pushes for greener maritime industries.

MCUs control specific marine functions like depth sensing, requiring compact, pressure-resistant wiring, especially in underwater drones. PCBAs, vulnerable to corrosion, need protective interfaces. Avertronics’ conformal-coated designs and micro-connectors ensure durability, as seen in underwater drone projects enhancing precision maneuvering. Their waterproof marine connectors drive sustainable marine e-mobility across shipping and exploration.

Ground-based e-mobilities such as e-bikes, e-scooters, and e-motos are central to urban transport, requiring compact, durable powertrains to navigate city environments. Connectivity for Motors, Batteries, Controllers, ECUs, MCUs, and PCBAs must withstand vibrations, frequent use, and weather exposure. Avertronics’ e-bike solutions and e-scooter/e-moto solutions provide customized connectivity for optimal performance.

Ground vehicle motors, like hub or mid-drive units, require high-current wiring for quick acceleration, facing wear from road shocks and debris. Avertronics’ flexible harnesses ensure reliable power, extending motor life in e-bike case studies. Their solutions support urban commuting demands efficiently.

Batteries in ground e-mobility need safe connectivity for frequent charge cycles, with thermal management critical. Avertronics’ anti-spark connectors support fast-charging, reducing downtime as seen in e-scooter fleet applications. Their designs enhance user convenience significantly.

Controllers and ECUs manage ride dynamics, requiring low-latency wiring. Avertronics’ shielded harnesses improve control in traffic, enhancing safety. MCUs and PCBAs benefit from compact, durable connectivity, with Avertronics’ powertrain expertise making ground e-mobility safer and more efficient.

Despite domain-specific differences, e-mobility powertrains face shared connectivity challenges: thermal management for batteries and motors, vibration impacts on PCBAs and controllers, and safety risks like high-voltage sparking. These issues transcend air, sea, and ground applications, requiring universal solutions that can be adapted to varying needs. Thermal stress, for instance, affects battery longevity in drones as much as in marine vessels, often exacerbated by fast charging or high discharge rates that generate heat. Vibrations—whether from flight turbulence, ocean waves, or bumpy roads—threaten connector stability and solder joints across all platforms. Safety hazards, particularly arcing in high-voltage systems, pose risks of fire or system failure universally, demanding standardized protective measures.

Avertronics tackles these unified challenges with innovative, cross-domain solutions. Their modular wire harnesses allow scalability, fitting diverse powertrain layouts while maintaining ease of maintenance. Anti-spark connectors, a hallmark of their technology, prevent dangerous electrical discharges during connection, a critical feature for high-voltage batteries in any vehicle type. High-IP rated connectors (e.g., IP67/IP68) offer environmental protection against water, dust, and corrosion, applicable from marine boats to dusty urban e-scooters. Additionally, advanced insulation materials in their harnesses provide thermal resistance, reducing overheating risks across applications.

Case studies illustrate the impact of these innovations. In a cross-domain project involving a fleet of delivery drones and e-scooters, Avertronics’ harnesses reduced thermal failures, thanks to integrated heat-dissipating designs. Another example from a marine and ground vehicle manufacturer showed drop in vibration-related connector issues after adopting Avertronics’ dampening solutions. These outcomes highlight how their technologies not only address common challenges but also enhance powertrain reliability universally. By focusing on adaptable, robust connectivity, Avertronics ensures e-mobility systems perform optimally regardless of environment, supporting the global shift to sustainable transport.

The horizon of e-mobility powertrain connectivity is marked by rapid technological evolution, promising smarter, more sustainable systems. Emerging trends include AI-driven ECUs for autonomous operation, processing vast data sets for real-time decision-making in drones and ground vehicles alike. IoT-integrated MCUs enable predictive maintenance, alerting operators to potential failures before they occur, a feature critical for fleet management across domains. Sustainable battery technologies, such as solid-state cells with higher energy densities, are set to redefine power storage, requiring next-gen connectors to handle increased capacities and faster charging.

Connectivity challenges in this future landscape include ensuring high-speed data transfer for AI and IoT functionalities, necessitating advanced wiring with minimal latency. Cybersecurity emerges as a concern, with connected powertrains vulnerable to hacking, demanding encrypted communication protocols. Material sustainability pushes for recyclable harnesses and eco-friendly insulation, aligning with global environmental goals. Avertronics is at the vanguard, developing smart harnesses for wireless charging integration—eliminating physical connectors in some scenarios—and lightweight, energy-efficient wiring for enhanced motor efficiency.

Their R&D focuses on biocompatible materials for wiring, reducing environmental impact, and modular designs for easy upgrades as technologies evolve. In partnerships with e-mobility innovators, Avertronics’ prototypes for IoT-enabled connectivity have shown improvement in maintenance scheduling accuracy, per early testing data. Their vision includes supporting a carbon-neutral transport ecosystem, with connectivity solutions that adapt to emerging powertrain paradigms. As e-mobility advances, Avertronics’ forward-thinking approach ensures they remain leaders, addressing future challenges while driving innovation in powertrain connectivity.

Powertrain connectivity stands as the cornerstone of the e-mobility revolution, unifying Motors, Batteries, Controllers, ECUs, MCUs, and PCBAs to deliver seamless performance across air, sea, and ground domains. From lightweight harnesses powering drones through turbulent skies to corrosion-resistant connectors safeguarding marine batteries in salty waters, and durable wiring supporting e-bikes on bustling city streets, connectivity ensures efficiency, safety, and reliability in every application. The challenges—thermal stress, vibration, environmental exposure, and safety risks—are formidable, yet they are met with innovative solutions that adapt to the unique demands of each domain. This intricate balance of technology and adaptability is what propels e-mobility forward, transforming transportation into a sustainable, accessible future.

Avertronics emerges as a trusted partner in this journey, offering a portfolio of cutting-edge connectivity solutions tailored to the diverse needs of e-mobility powertrains. Their custom wire harnesses, waterproof connectors, and anti-spark technologies address the toughest obstacles, ensuring that powertrain components operate at peak performance whether in a drone, boat, or e-scooter. Case studies and real-world applications—from increasing drone flight times to reducing maintenance in electric ferries—demonstrate Avertronics’ tangible impact on efficiency and safety. Their commitment to innovation, coupled with a vision for future trends like AI integration and sustainable materials, positions them as leaders in shaping the next generation of electric transport.

For manufacturers, engineers, and businesses seeking to pioneer or enhance e-mobility solutions, Avertronics offers unmatched expertise and customized connectivity options. Whether you’re developing the latest aerial delivery system, designing an eco-friendly marine vessel, or scaling an urban e-bike fleet, their products and support can elevate your project.

Inquiry Today, Learn more: Avertronics’ E-Mobility Solutions today to explore their comprehensive range of powertrain connectivity solutions, request technical specifications, or connect with their team for personalized consultations. Embrace the future of transportation with a partner dedicated to powering progress—contact Avertronics now and transform your e-mobility vision into reality.